Reliability Redefined

Consistently producing square boxes is the goal of corrugated converters. This requires well-maintained machinery, knowledgeable operators with a clear understanding of box-making, and the right tooling.

To support converters in achieving this goal, Sauer System offers a comprehensive Asset Management Program. The program combines an expert field team with a wide range of proven and innovative solutions tailored for slotting and folding operations. Key Services include:

- Regular replacement of slot/score section tooling

- Ongoing maintenance and adjustments

- Maintenance and calibration of Sauer upgrades

- Routine machine inspections

The program is an evolution Sauer’s established tooling and upgrade offerings. Sauer’s field team can manage significant upgrades such as conversions from solid slotter heads to split slotter heads and folding section enhancements.

With Sauer System’s Asset Management Program, converters can ensure optimal machine performance, long-term reliability, and consistently square boxes.

Programs begin with a comprehensive evaluation of the machine and detailed discussions with plant personnel about both current and historical issues—such as inconsistent folding, slotting section problems causing downtime, and components wearing out sooner than expected. Based on these findings, Sauer will recommend tailored tooling and upgrade solutions to address these concerns and establish a reliable baseline for machine performance.

After this initial phase is complete, the program transitions into routine maintenance sessions to ensure continued reliability and optimal operation.

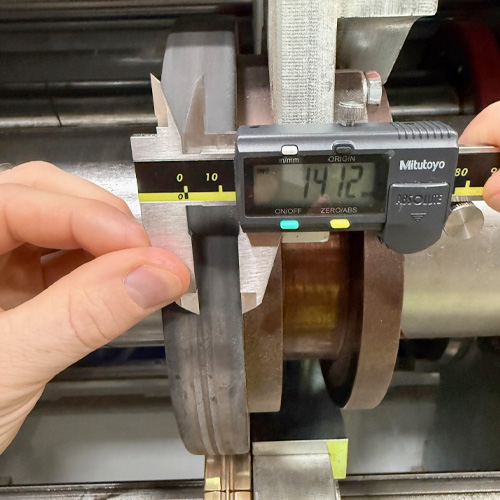

In the slotting section, Sauer technicians perform comprehensive maintenance and upgrades to ensure optimal performance. Some Examples Include:

- Replacing upper and lower slotter heads

- Installing new male slotting knives and female slotting blades

- Replacing slot strippers, male and female scoring rings and heads, and precreasers

- Installing new polyurethane creaser and precreaser anvils

Technicians will also inspect and replace yoke wear strips, blocks, and guides as needed. They will review the condition of pull collars and other tools that transfer the board through the machine, recommending and carrying out replacement when appropriate. Maintenance and replacement of glue tab cutting components are performed as required.

Whenever existing strippers, scorers, or tab cutting tooling can be upgraded, Sauer will recommend enhanced solutions, ensuring converters always benefit from the most effective tooling and asset management practices. All components in the slotting section are thoroughly inspected for wear and evaluated based on their impact on board quality.

In the folding section, Sauer technicians conduct detailed checks on each element that influences box folding. They ensure the rails are parallel, identify and address any mechanical issues, and recommend replacement of belts and pulleys as needed. They also restore and maintain riding surfaces, position and fine-tune folding rods for optimal performance.

For legacy equipment or unique folding sections, Sauer’s field engineers have the expertise to develop and recommend custom-made or newly designed parts to enhance functionality.

As part of this program, Sauer has designed innovations such as split folding belt pulleys, folding section belt guides, Sauer’s advanced male scoring profiles, and the evolution of bonded polyurethane female scorers that continue to improve box quality and machine efficiency.

Training is also available to enhance operator skills and machine performance. Training options range from general machine operation and best practices to advanced programs focused on the intricacies of the slotting section, including how to troubleshoot gap variation by understanding alignment and center-lining.

The Asset Management Program was developed as installations exposed converters’ desire for a more comprehensive service model.

Originally, the program focused on installing Sauer parts, tooling, and upgrades. However, the field team soon recognized that plants could benefit greatly from Sauer’s specialized attention to critical machine sections and the impact these areas have on board transfer and fold quality. This realization shaped the evolution of the program into a comprehensive asset management solution.

“Tapping into our expertise is a major part of the value proposition,” says Peter Sauer, VP of Sales. “Box plants are busy running their operations and often lack a dedicated person on site to thoroughly investigate the machine and its nuances related to reliable operation and folding. Conducting detailed checks to identify which parts need attention to ensure square box folding is a crucial component of our service.”

The ultimate goal of the program is simple: square boxes every time.

The realization was that when we visited a plant, we would replace tooling, calibrate and adjust slotting and scoring section components, tune the folding rails, and successfully produce square boxes,” Sauer explains. “However, on subsequent visits, we found worn and misaligned yokes, heads, and folding section parts again. Over time, we developed improved solutions and began promoting these across plants with similar machines. Our objective is to build long-term partnerships with plants desiring routine service."

More than just providing reports, plants need hands-on assistance. “Sauer’s field team does far more than identify parts needing replacement or maintenance — they actively replace and adjust them.”

“We really get into the nitty-gritty of what makes a machine work,” Sauer adds, highlighting the deep technical expertise central to the program’s success.